With the continuous progress of science and technology and the continuous development of industrial automation, industrial robots have become an indispensable and important role in modern manufacturing. Industrial robots replace manual labor to complete high-intensity repetitive work, improve productivity while ensuring product quality.

As the core part of the robot, the robot controller is mainly used to ensure that the robot's joints are executed in accordance with the predetermined trajectories and movements through calculation and control signal output. The controller is responsible for monitoring and adjusting the position, speed and acceleration of the joint actuators, so as to make the robot's movements precise and stable. And through programming and algorithm setting, the controller can accurately calculate the movement trajectory of each joint to achieve the desired position, attitude and trajectory.

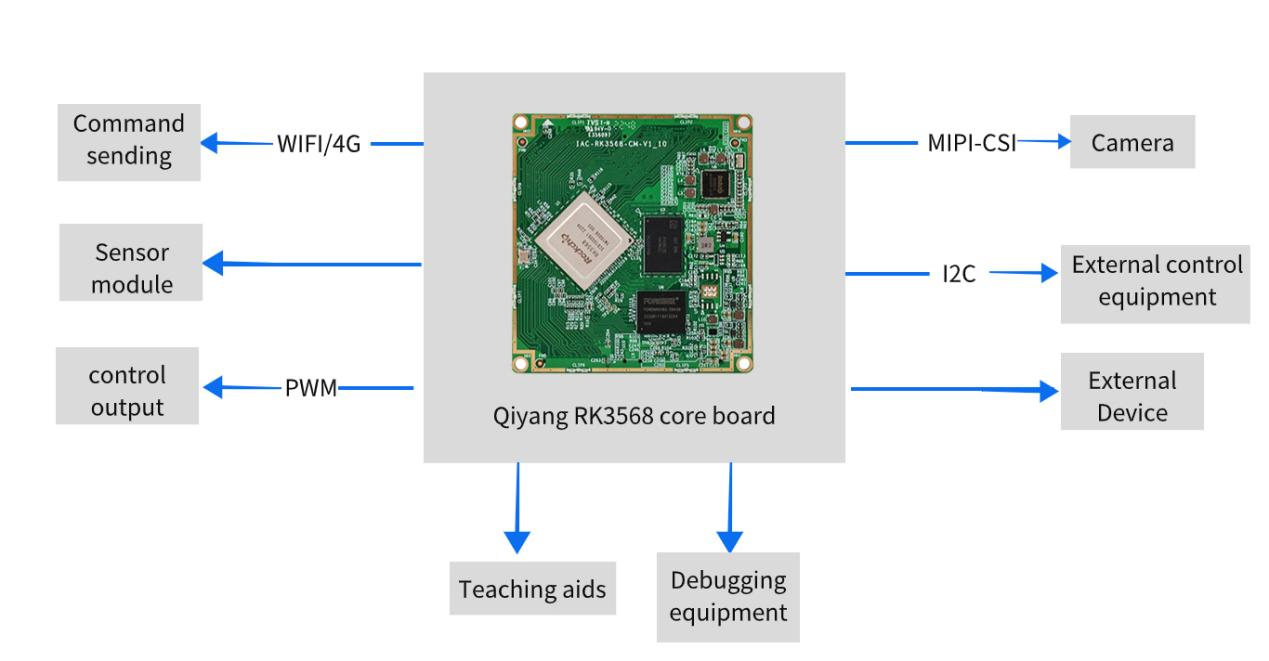

The controller of industrial robots includes the main control board, sensor interface, actuator interface, IO interface and so on. The main control board is equipped with processing and storage capabilities to execute complex algorithms and control strategies. The sensor interface is used to connect and receive sensor signals, the actuator interface is used to connect and control each actuator, and the IO interface is used to communicate with external devices to realize linkage and data exchange.

Based on the above requirements, Qiyang's industrial-grade RK3568 core board can be used as the main control platform of the robot controller.

The Qiyang RK3568 core board is designed and developed based on the Rockchip RK3568 processor, with a quad-core 64-bit Cortex-A55 architecture with a main frequency of up to 1.8GHz, which provides powerful performance support with excellent computing and processing performance. 1TOPS arithmetic NPU, which meets the lightweight end-side AI computation, realizing, for example, functions such as image recognition, object detection, and target tracking.

The Qiyang RK3568 core board is designed and developed based on the Rockchip RK3568 processor, with a quad-core 64-bit Cortex-A55 architecture with a main frequency of up to 1.8GHz, which provides powerful performance support with excellent computing and processing performance. 1TOPS arithmetic NPU, which meets the lightweight end-side AI computation, realizing, for example, functions such as image recognition, object detection, and target tracking.

The core board is equipped with a dual-core Mali-G52 GPU supporting graphics processing and 3D acceleration, which can be applied to robot visual recognition and navigation tasks, thus improving robot autonomy, flexibility and efficiency.

The core board supports a variety of communication interfaces such as 4G/5G, WiFi, Ethernet, etc. It provides industrial robots with a variety of communication and networking capabilities, transmits robot status and control signals in real time, and communicates and collaborates with other devices. It realizes data exchange, remote control, sensor data acquisition, firmware upgrade and other functions.

The core board supports a variety of peripheral interfaces such as MIPI, USB, SATA, CAN, UART, GPIO, etc., which can be connected to external devices such as cameras, sensors, laser scanners and a variety of peripheral devices, realizing the industrial robots to flexibly and intelligently respond to a variety of tasks and application scenarios, and improving the efficiency and flexibility of industrial production.

During the working operation of industrial robots, video monitoring and troubleshooting can be used to monitor the running status and working process of industrial robots in real time, so as to find and solve the abnormal faults in time. The core board supports EDP, MIPI, LVDS, HDMI and other display interfaces, through the connection of the display interface, the video signal can be transmitted to the monitor or monitoring equipment, so as to realize the real-time observation of the robot's work by the operator, and to solve the possible faults in time.

The pan application of industrial robots for the modern manufacturing industry has brought great changes and development, not only improve the production efficiency and quality, but also improve the working environment and personnel safety. With the continuous innovation and improvement of science and technology, industrial robots in the future manufacturing industry will play a greater role in promoting the sustainable development of intelligence.