The coal mining environment is complex and the degree of danger is high. Every accident brings a bloody lesson to the industry. The safety problem is also a difficult problem to be solved urgently by the government and the industry.With the development of technology, coal mine intelligence has become a new direction of industry exploration, and reducing safety risks is also one of the important goals of intelligence.The key to safety production is to prevent micro-growth. The intelligentization of coal mine safety production requires remote real-time monitoring of all kinds of data of underground working face, avoiding all kinds of accidents and building a safe production defense line.

Coal Mine Safety remote monitoring system adopts Internet of Things, cloud computing, AI and other technologies. Through installing cameras and various sensors under the mine, it can monitor the working conditions and violations of workers in the mine in real time, monitor the fan, temperature, water level, gas content, oxygen content, carbon monoxide content, air pressure and other data in the mine, and transmit the monitoring data to the cloud through IoT gateway. When the gas content, water level, when the concentration of carbon monoxide exceeds the preset standard of the system, an audible and visual alarm is triggered to remind the underground personnel and the monitoring and management personnel on the well of the abnormal situation until the fault is eliminated.The background management personnel realize the monitoring, analysis and storage of video and image information through the remote monitoring system. The management personnel can intuitively understand the underground operation situation, and the system can automatically identify behaviors such as not wearing a helmet, leaving the post without permission, breaking into dangerous areas, etc. to ensure the safety of the underground production environment.

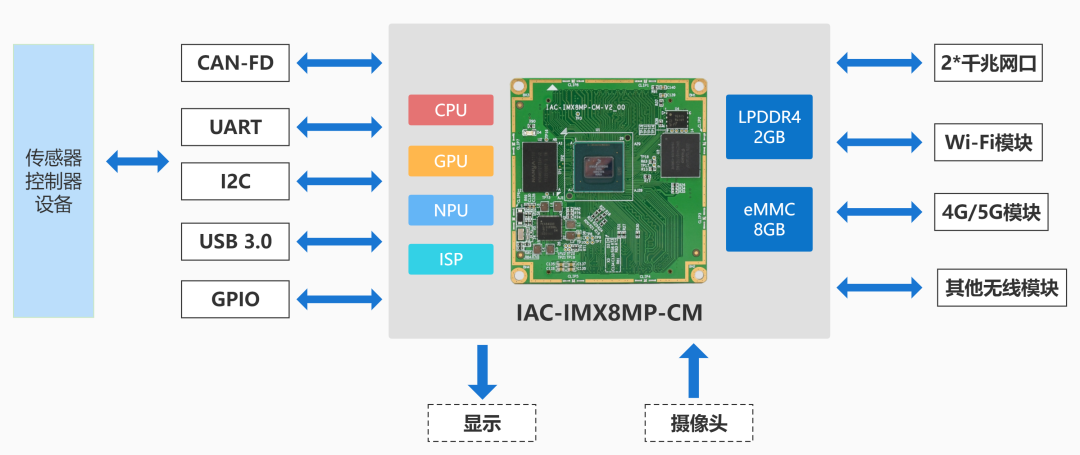

The data collection and transmission of the coal mine safety remote monitoring system are realized through the Internet of Things gateway. The environment under the mine is complex and there are problems such as electromagnetic interference, dust, high temperature, humidity, etc. Due to the requirements of system stability, higher conditions are put forward for the Gateway hardware. Qiyang provides a variety of industrial core boards that can be used to build gateway data transmission terminals. IAC-IMX8MP-CM, as a core board with strong computing power, high flexibility and high reliability, is very suitable for building industrial edge computing gateways.

I. MX8M Plus core board is based on quad-core Cortex-A53, with a dominant frequency of up to 1.8GHz. It integrates the NPU of neural network acceleration unit, provides 2.3tops computing capability, and supports machine learning function, enabling AI applications such as face recognition, electronic fence, off-the-job detection, etc. to be implemented on the industrial edge.

The core board comprehensively leads to processor resources, and the supporting baseboard leads to interfaces such as dual gigabit network ports, 3 channels of USB3.0, 4 channels of RS232, 1 channel of RS485, 2 channels of CAN-FD, etc. It supports multiple DI and DO interfaces to meet the needs of industrial field interfaces.

In terms of data transmission and communication, it supports dual gigabit network ports to realize stable data transmission, supports wireless communication such as 5G, WIFI and Bluetooth, supports expanding various wireless communication modules, collects data of multiple sensors in the mine in a wireless way, and ensures real-time transmission of various data to the cloud platform through various wired wireless communications, providing support for data visualization, analysis and scientific decision-making.

The core board supports dual cameras, and the processor has dual image signal processor ISP, which processes front-end camera signals, and can still realize high-speed image acquisition and processing under the condition of weak mine light, and output high-quality video images; It leads to the M.2 interface that can expand SSD module to meet the storage demand of massive data.

Industrial design is available, with high anti-interference performance and wide working temperature range of-40℃ ~ + 85℃, which is suitable for industrial applications in complex environments; Linux operating system is supported, and various official open source software platforms are supported, which is convenient for users to better carry out system design.

Coal Mine Safety remote monitoring system is an important component of coal mine intelligence, accompanied by 5G full coverage, remote control, remote monitoring, robot inspection...... The intelligent structure of coal mine is gradually formed from point to surface.