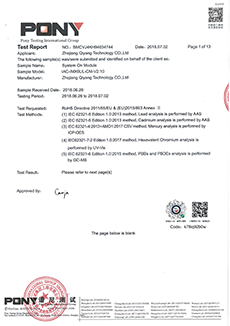

Management System Certificate

Material Security

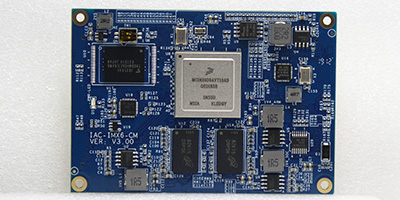

All components used on the embedded system on module and development board are selected from famous brands, regular outlets, and superior quality devices. All incoming material will be strictly tested. Guarantee the products’ quality from the root cause.

Processor manufacture

Component brand

Production Guarantee

Strictly enforce the quality management system ISO9001:2015 to control the production process, use the specialized facilities and inspection instruments to ensure superior quality.

Process:

SMT Machinery

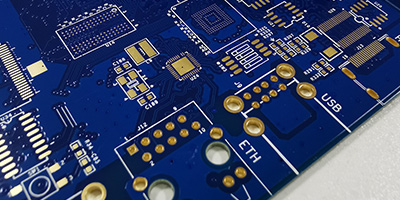

Quality Assurance

PCB adopts a 4~10-layer golden immersion design, fully considers the signals’ integrity and anti-interference, precise technology, not easy for deformation, with long service life.

Industrial grade is selectable, harsh temperature grade test to ensure the system on module could run stably at the temperature range from -40 °C ~ to 85°C.

Each unit needs to through 24~72 hours regular/ high temperature & low-tem- perature aging, and use the professional method to do a full test on the SOM Module’s performance, functions, to ensure each unit’s quality.

Each unit should be with its own serial no. and MAC address, it is easy for batch management, incoming material tracing, and product tracking.