Laser marking machine is a kind of marking and engraving equipment using laser technology, as a subdivision of laser technology application, is the earliest introduction of the industrial market of a class of laser equipment, which uses a laser beam on the surface of the workpiece for engraving, marking, commonly used in industrial production of material marking, product traceability, anti-counterfeiting marking and other applications, has been widely integrated into the industrial manufacturing scenarios.

Laser Marking Machine Working Principle

Laser Marking Machine Working Principle

The laser marking machine utilizes a high-energy laser beam generated by a laser, which is focused into a very small spot through a system of lenses and mirrors to engrave on the surface of the workpiece. The intensity of the laser beam can be controlled by adjusting the power of the laser to achieve different depths and colors of the marking effect. Laser marking machine is widely used in automotive parts, electronic equipment, medical equipment, jewelry, packaging materials and other industries, it can be engraved on the product of text, patterns, two-dimensional code and other information, to help improve product identification, anti-counterfeiting and quality management.

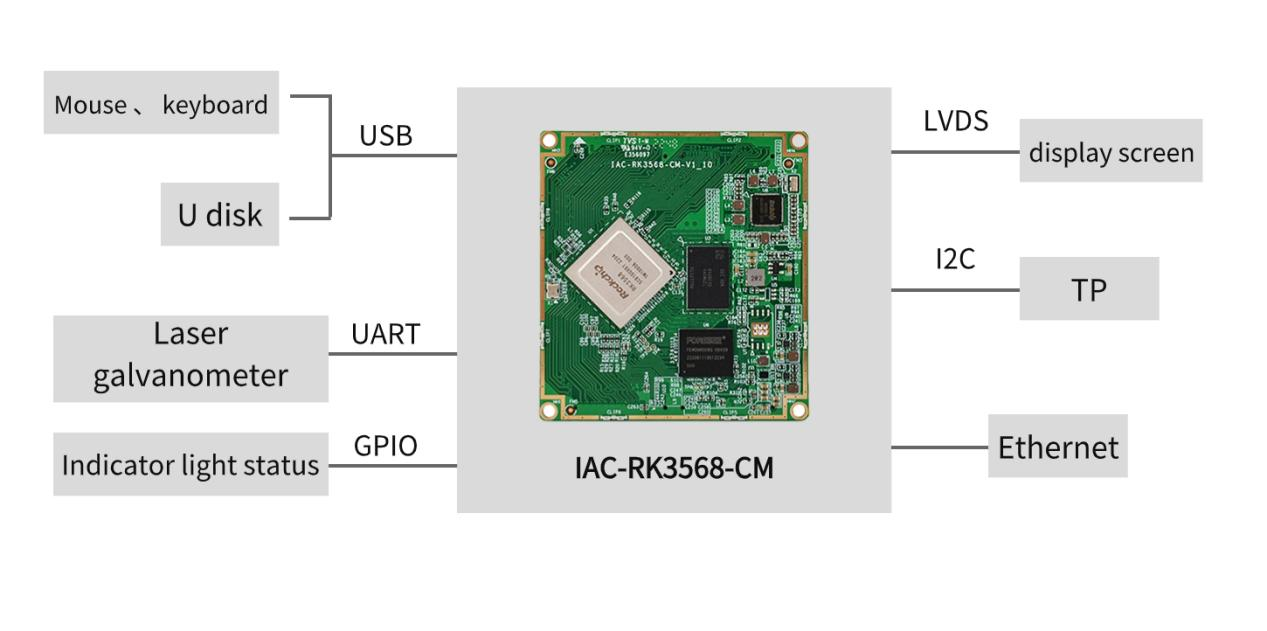

The main control part of the laser marking machine can be realized by using Qiyang RK3568 core board, the core board adopts quad-core A55 architecture, the main frequency is up to 2.0GHz, the integrated dual-core architecture GPU and high-efficiency NPU, which has a powerful system operation arithmetic, and it can collect and control the coordinated operation of each functional system and sensor equipment of the laser marking machine.

The main control part of the laser marking machine can be realized by using Qiyang RK3568 core board, the core board adopts quad-core A55 architecture, the main frequency is up to 2.0GHz, the integrated dual-core architecture GPU and high-efficiency NPU, which has a powerful system operation arithmetic, and it can collect and control the coordinated operation of each functional system and sensor equipment of the laser marking machine.

Laser marking machine in the process of operation, the need for human-computer interaction through the display side, Qiyang RK3568 core board supports MIPI-DSI, LVDS, eDP, HDMI multiple display interfaces, support for three-screen same display / heterodyne display, can realize the laser marking machine status monitoring, parameter settings, image preview and operation control applications, with a clear display effect and smooth operation experience.

In complex industrial environments, industrial control equipment can be affected by environmental factors such as high load, strong interference and vibration. Qiyang RK3568 core board can be equipped with industrial-grade specifications, with multiple protection guarantees such as anti-static, anti-magnetic electronic interference, etc., which can cope with all kinds of harsh tests in industrial environments, and provide performance support for 7*24 hours of stable operation.

The laser marking machine needs to transmit data and work together with other devices in the process of operation. The core board supports interfaces such as UART, SPI, I2C, Ethernet, etc., which can communicate with other devices and enhance the function and performance of the overall system.

The laser marking machine usually needs to run for a long time, and in the process of running, it will encounter sensing failures, communication anomalies, etc., which cause the system to fail to respond. The core board supports the watchdog function, which can detect these abnormalities and trigger the corresponding processing mechanisms, such as alarms, recording abnormal information, etc. It can also monitor the operating status of the main control system to ensure the normal operation and safety of the system.

In the future, with the gradual promotion of "Industry 4.0" and "Made in China 2025" national strategy, automation and intelligence in the field of laser marking will become an inevitable trend of development, and highly intelligent multi-functional laser marking equipment will continue to emerge and greatly improve the efficiency of industrial processing, and realize efficient production management. Greatly enhance the efficiency of industrial processing, to achieve efficient production management.