With the rapid development of communication and network technology and the popularity of the Internet, industrial management has tended to be data-driven, networked and intelligent. In a smart factory, the use of industrial IoT to achieve industrial data collection and control has become an essential part.

Traditional industrial data acquisition and control systems usually need to connect multiple data acquisition devices for high-speed communication, and undertake complex data processing, high-definition multimedia display and other functions, while embedded systems based on ARM + FPGA architecture come with rich peripheral interfaces, with high-definition display, high-speed transmission and other functions, but also to complete the task of high-speed acquisition of industrial data.

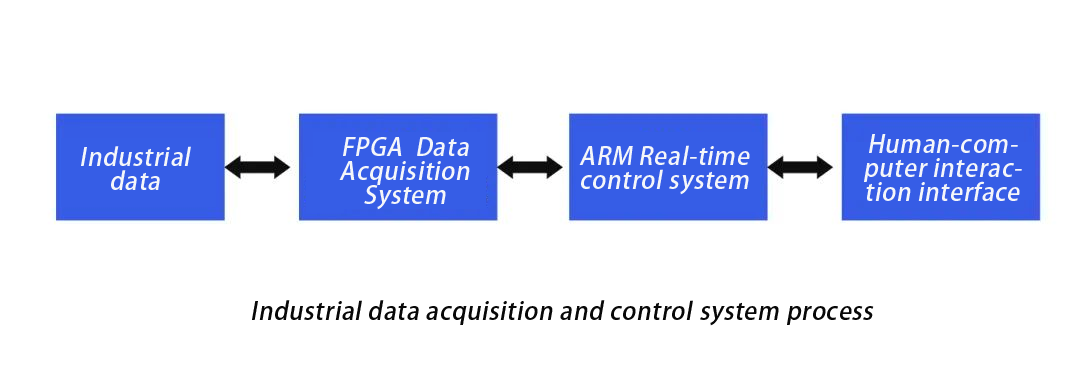

The industrial data acquisition control system is divided into two parts: high-speed data acquisition system and embedded human-computer interaction system. The high-speed data acquisition system is responsible for collecting data in the industrial production process in real time. The embedded human-computer interaction serves as the master control center, coordinates and manages each module and resource scheduling, receives FPGA data, visualizes the results and realizes human-computer interaction. In addition, the master control center can also use the communication module to transmit the obtained data to the industrial MES + ERP system to store industrial data in cloud, which not only reduces the risk of manual data entry, but also reduces the waste of human resources.

The industrial data acquisition control system is divided into two parts: high-speed data acquisition system and embedded human-computer interaction system. The high-speed data acquisition system is responsible for collecting data in the industrial production process in real time. The embedded human-computer interaction serves as the master control center, coordinates and manages each module and resource scheduling, receives FPGA data, visualizes the results and realizes human-computer interaction. In addition, the master control center can also use the communication module to transmit the obtained data to the industrial MES + ERP system to store industrial data in cloud, which not only reduces the risk of manual data entry, but also reduces the waste of human resources.

Solution of industrial data acquisition and control system

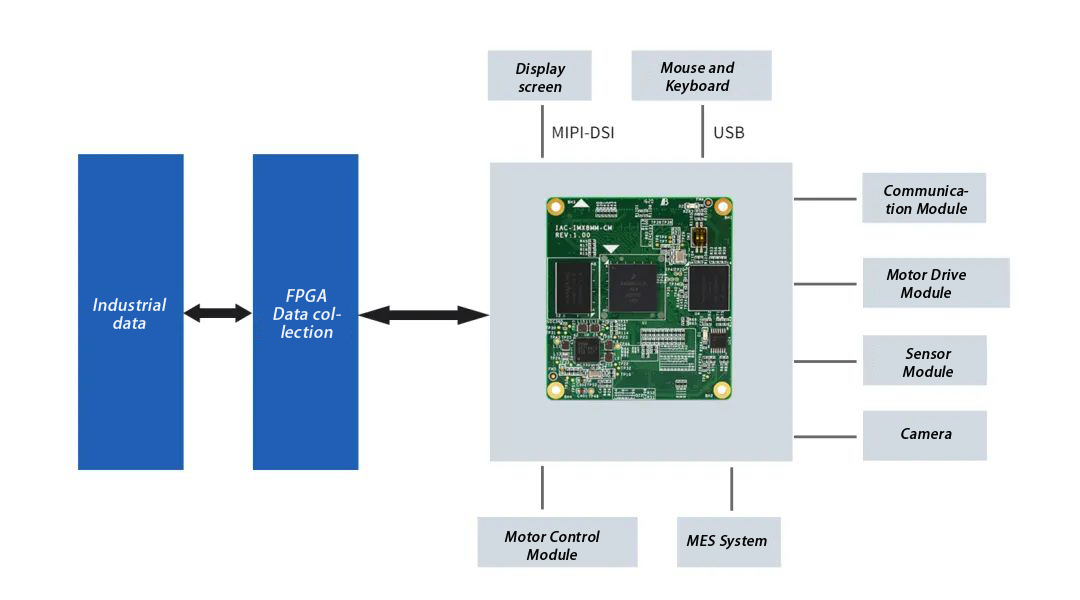

The main control equipment of the industrial data acquisition and control system can be realized by using the core board of Qiyang IAC-IMX8MM-CM. Based on NXP IMX8M Mini processor, it adopts four-core Cortex-A53 and single-core Cortex-M4 architecture, which can provide excellent data processing capability and human-computer interaction experience, and can control the motor drive module in real time to meet the data processing, task scheduling and human-computer interaction requirements of the real-time control system.

The core board supports 1080P60 H.265 and VP9 decoding and MIPI HD display. Industrial data acquisition and control systems usually need to process a large amount of video data, including monitoring images and image recognition. Hardware-based decoding can transfer the load of video processing from CPU to specialized hardware modules, reducing CPU pressure and improving system stability and response speed. It can also be connected to a high-resolution display screen to realize a good human-computer interaction experience;

With rich interface resources, it can be used to connect various sensors, actuators, motor drive modules, mouse and keyboard equipment, etc., and can realize industrial data collection and control of various signals and data, and realize monitoring and control of production process;

It supports dual Gigabit Ethernet and provides fast data transmission and connection capabilities to meet the requirements of industrial data acquisition and control systems for high broadband and low latency. It also supports dual communication interfaces such as CAN, I2S and I2S, providing reliable, high-speed and real-time data transmission methods, providing support for the normal operation and efficient performance of industrial data acquisition and control systems;

It adopts industrial grade electronic components and industrial grade temperature and width design to ensure the stability and reliability of products and meet the requirements of industrial application environment.

With the rapid development of information technology and communication technology, the intelligent industrial system is gradually formed. The industrial data acquisition and control system has realized the functions of real-time industrial data acquisition and processing, intelligent analysis and decision-making, remote control, industrial automation and so on, providing efficient, intelligent and sustainable development solutions for industrial enterprises.